Knowledge

We are sharing Knowledge, innovations, Case Stories and Best Practices.

Quest RELIABILITY team will keep updating this space with information on development in the industry, technology updates, case stories and best practices followed in the CBM and Reliability world.

Electric Motors:

Motors are the driving force of industry or commercial facility.

An electric motor is a machine that converts electrical energy into mechanical energy. In normal motoring mode, most electric motors operate through the interaction between an electric motor’s magnetic field (Rotor) and winding currents(Stator) to generate force within the Motor.

The distance between stator and Rotor must be equal and balanced, and the force should be uniform.

Quest RELIABILITY team helps in analyzing motor faults in early-stage and prevent unplanned downtime. The following technology used to detect and predict the most common failures of electric motors

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Looseness, Resonance, and Bearing faults |

| Motor Current Signature Analysis/ESA | Eccentric rotor-variable rotating air gap Thermal rotor bow, Broken or cracked rotor bars Lamination problems |

| IR Thermography | Lamination shortens and heating of the Motor |

| Oil Analysis | Bearing wear through oil condition |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear |

Pumps & Compressors:

Pumps: A pump is a machine that moves a fluid (either or liquid) from one place to another.

Compressor: A compressor is a machine that squeezes gas into a small volume and pumps it somewhere else at the same time.

Quest RELIABILITY team helps in analyzing Pumps & Compressors and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Pumps & Compressors

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Looseness, Resonance, Bearing faults, Soft foot, and Cavitation. |

| Motor Current Signature Analysis/ESA | Major Misalignment(Surface temperature) and Last stage of bearing failure |

| Oil Analysis | Bearing wear through oil condition analysis |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear and steam traps |

Fans & Blowers:

Fans and blowers provide air for ventilation and process requirement

Fans have the specific pressure ratio up to 1.11

Blowers have a particular pressure ratio from 1.11 to 1.20

Quest RELIABILITY team helps in analyzing Fans & Blowers and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Fans & Blowers

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Wear, Looseness, Resonance, and Bearing faults. |

| IR Thermography | Major Misalignment and last stage of bearing failure |

| Oil Analysis | Bearing wear through oil condition |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear and steam straps |

Pumps & Compressors:

A reciprocating compressor is a positive- displacement equipment with pistons to compress gas and to deliver at high pressure.

It is an engine that utilizes one or more pistons to convert pressure into rotating motion.

Quest RELIABILITY team helps in analyzing Reciprocating Compressor and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Reciprocating Compressor

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Damaged bores, Bearing defects, Losseness, and misalignment. |

| P-V Analysis | Efficiency and Econonomy, Valve and other component life |

| Ultrasound | Valves and Injector condition analysis, leaking/damaged valves |

Gearbox:

Gear is a toothed wheel with a mechanical method of transferring energy from one device to another. The gearbox is a system of gears which alters torque and speed between a drive and a driven system. They can also change the direction of the axis of rotation and can change rotary motion to linear motion.

Quest RELIABILITY team helps in analyzing Gearbox and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Gearbox

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Looseness, Resonance, Bearing fault, Gear teeth damage and wear |

| Oil Analysis | Analyze oil health, oil contamination and machine wear. |

| Wear Particle Analysis (WPA) | Bearing, Gear and other components wear through oil particle analysis |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear |

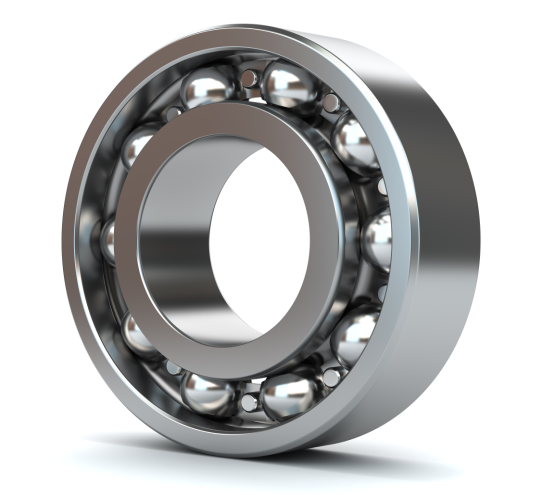

Bearings:

The rotating shaft is to transmit power from one end to another, which need support to ensure stability and frictions less rotation.

The support for the shaft is known as “Bearings.”

The shaft has running fit in a bearing. All bearings are provided with a lubrication system to reduce friction between shaft and bearings.

Quest RELIABILITY team helps in analyzing Bearings and prevent unplanned downtime. The following technology used to detect and predict the most common failures

| Technology | Fault Symptoms |

|---|---|

| Vibration | Inner race, Outer race, Ball spin and Cage rate frequency |

| Oil Analysis | Bearing wear through oil contamination |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear |

| High-Frequency Detection | Using high-frequency vibration data we can analyze the bearing condition at an early stage |

Belts and Pulleys:

GA belt drive is one of the most cost-effective means of power transmission. The drive depends on the friction between the belt and the pulley to transmit power between drive and driven pulley. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need to be parallel.

Quest RELIABILITY team helps in analyzing Belts and Pulleys to prevent unplanned downtime. The following technology used to detect and predict the most common failures of Belts and Pulleys

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Eccentric sheaves, Looseness, Resonance, and Bearing faults |

| Oil Analysis | Bearing wear through oil condition |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear |

| Stroboscope | Belt resonance, Belt damage |

Coupling:

It is a mechanical element used to connect two shafts of a transmission system and transmit the torque from one shaft to another.

Depending upon the coupling type, it can allow small misalignment and even its a flexible coupling, and it has no excuse for excessive misalignment.

Misalignment reduces the coupling life up to a great extent.

Quest RELIABILITY team helps in analyzing Coupling and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Coupling

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Looseness |

| IR Thermography | Last stage of Coupling damage |

| Stroboscope | Shim damage in couplings |

Rolls:

The various applications on the paper machine require a variety of rolls, and other process industry also has many applications of the rolls.

If any unexpected roll bearing failure, then it would result in a massive loss to the plant. In many applications, rolls are slow speed which makes very hard to analyze its condition through a traditional vibration analysis program.

Quest RELIABILITY team helps in analyzing Paper Machine Rolls and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Paper Machine Rolls

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Looseness, Resonance, and Bearing faults and Damaged roll profile |

| IR Thermography | Last stage of bearing failure |

| Oil Analysis | Bearing wear through oil condition |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear |

Mills:

A mill is a device that breaks solid material into smaller pieces by grinding, crushing, or cutting. Mills are a vital part of the operation in many process industries.

There are many types of mills and many types of materials processed by them.

Quest RELIABILITY tteam helps in analyzing Mills and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Mills

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Looseness, Resonance, and Bearing faults |

| IR Thermography | Last stage of bearing failure |

| Oil Analysis | Bearing wear through oil condition |

| Ultrasound | Detect lubrication problems and very early-stage of bearing wear |

Turbine:

A turbine is a rotary mechanical device that extracts energy from a fluid form and converts it into useful work. The work produced by a turbine can be used for generating electrical power when combined with a generator.

Quest RELIABILITY team helps in analyzing Turbine and prevent unplanned downtime. The following technology used to detect and predict the most common failures of Turbine.

| Technology | Fault Symptoms |

|---|---|

| Vibration | Unbalance, Misalignment, Looseness, Resonance and Bearing faults |

| Oil Analysis | Bearing wear through oil condition |

Saturday Success Academy

Your education in the classroom training is one aspect of experience in your career, but learning doesn’t stop there. Enhance your learning experience with Quest RELIABILITY by attending extended learning workshops.

This program is intended for providing an extended learning opportunity for the students who want to learn about specific techniques which they hadn’t experienced at field.

We facilitate the students with hands on experience using portable analyzers, online systems, wireless sensors and software to experience the real-world problems and analysis. We can help students to understand specific technique example Bump Test, Run-up/Coast down, Orbit analysis, Laser Alignment and In-situ dynamic balancing.

You will gain a new idea from exploring and discussing concepts with your fellow peers and you will experience a step change in your career.

Case Stories

Case Stories page will be updated soon.