Quest reliability Trainings

Basic Vibration Analysis:

Objective:

To create awareness on importance of condition monitoring techniques which improves the availability of operating machines, problem diagnostics efficiency and effective maintenance strategies and to understand the basics of vibration analysis and its importance of implementation in your plant.

Maintenance Strategies

- Breakdown Maintenance

- Preventive Maintenance

- Predictive Maintenance

- Reliability Centred Maintenance

Condition Monitoring Techniques

- Over View

- Vibration Analysis

- Thermography

- Acoustic Emission

- Oil Analysis

- Wear Particle Analysis

- Electric Motor Testing

Vibration Analysis

- Basic Principles (Frequency & Amplitude)

- Data Collection

- Introduction to Phase

- Introduction to Time Waveform

- Introduction to Spectrum

Data Acquisition

- Types of sensors

- Basic differences between shaft vibrations and casing vibrations

- Types of Sensor Mounting and its importance

- Uses of Low sensitive and High sensitive accelerometers

Diagnosing Common Faults

- Unbalance

- Misalignment

- Mechanical Looseness

- Bearing Problems

- Common Electric Problems

- Common Gear Box & Belt faults

- Common Pump, Blowers & Compressor Problems

Reliability Improvement

- Importance of Dynamic Balancing

- Importance of Alignment

- Importance of Precision Lubrication

Course Details:

Duration:

3 days

Fee:

Rs 9,500/- Per Student

10th-12th August 2020

14th-16th December 2020

Advanced Vibration Analysis:

Objective:

This Course is intended for participants who had enough knowledge on basics of vibration and with minimum 18 months of practical experience on Vibration Analysis. By end of this course one should be clear about calculating forcing frequencies and conducting Phase analysis for conforming a fault. This helps you to understand how to diagnose different fault conditions of your equipment’s.

Principles of Vibrations

- Frequency & Period

- Introduction to Orders

- Amplitude (RMS, Peak, Peak-Peak)

- Displacement, Velocity and Acceleration

- Phase (Absolute & Relative)

- Natural Frequency and Resonances

Signal Processing

- Sampling

- Filters (Low Pass, Band Pass & High Pass)

- Time Windows

- Averaging

- Resolution & Band Width

- Noise Reduction

Data Acquisition

- Instrumentation

- Transducers and its mounting methods

- Proximity sensor conventions

- Measurement Locations

- Recognition of poor data

Condition Monitoring

- Equipment evaluation and prioritization

- Monitoring Programme Design

- Baseline assessments and trending

- Route Planning

Fault Analysis

- Unbalance

- Misalignment

- Mechanical Looseness

- Bearing Problems

- Common Electric Problems

- Common Gear Box & Belt faults

- Common Pump, Blowers & Compressor Problems

- Harmonics and Sidebands in Spectrum

- Resonance and Critical Speeds

Corrective Action

- Shaft Alignment

- Dynamic Balancing

Equipment Knowledge

- Electric Motors

- Pumps and Fans

- Turbines

- Rolling Mills and Paper Machines

- Rolling Element Bearings

- Journal Bearings

- Gear Boxes

Alarm Settings & Acceptance Testing

- ISO Standards

- Test Procedure

- Specifications and Standards

- Reporting

Course Details:

Duration:

4 days

Fee:

Rs 17,500/- Per Student

13th-16th July 2020

14th-17th September 2020

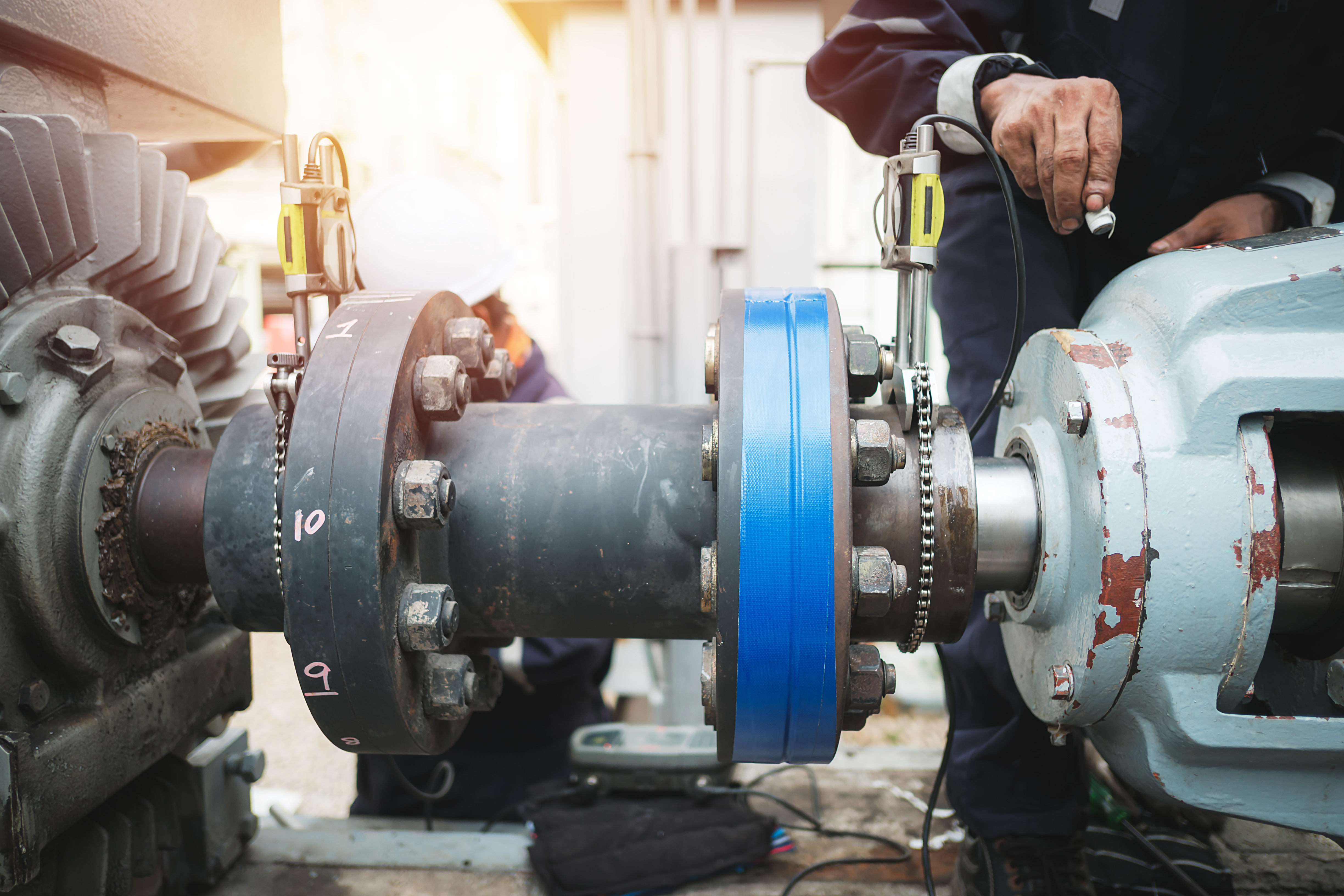

Laser Alignment and Dynamic Balancing:

Objective:

This course focuses on importance of performing Laser Alignment and Dynamic Balancing and how they can improve Machine Reliability. We also provide Hand-on Dynamic Balancing and Laser Alignment also with their benefits and methods. This can be an onsite course which enables opportunity to implement on real world applications.

Laser Alignment

- Introduction to Shaft Alignment

- What is misalignment?

- Importance of eliminating Soft Foot

- Pre Alignment Checks

- Dial Indicator

- Laser Alignment

- Importance of performing Laser Alignment

Dynamic Balancing

- What is Unbalance?

- Types of unbalance (Static, Couple & Dynamic)

- Understanding Vectors

- How vibration output unit affects phase angle

- Single Plane Balancing

- Dual Plane Balancing

- Three Point Four Run Method (Without Phase)

- Importance of performing Dynamic Balancing

Course Details:

Duration:

2 days

Fee:

Rs 12,500/- Per Student

13th-14th August 2020

17th-18th December 2020

Reliability:

Objective:

Quest Reliability offers this course as an introductory to Reliability Engineering and its important applications. This covers the foundation reliability concepts and methods, and how to apply the basic failure investigation techniques along with analysis tools, strategies and implementation of workplace improvements.

Best Practices

- Introduction

- Best Practices to do with maintenance and reliability

- Maintenance and Reliability Knowledge

Culture and Leadership

- Introduction

- Leadership and Organizational Culture

- Vision and goals

- Change Management

- Reliability Culture

Asset Criticality Ranking

- Mission and Costumer Impact

- Safety & Environmental Impact

- Preventive Maintenance History

- Corrective Maintenance History

- Mean Time Between Failures

- Chances of Failure

- Lead time of Spares

- Replacement Value

- Planned Utilization rate

Understanding Failures and Defect Eliminations

- Failure Patterns study

- Purchase and Transport

- Acceptance Testing

Work Management

- Introduction

- Work Flow and Roles

- Planning and Scheduling Process

- Measures of Performance

Material and Inventory Management

- Types of Inventory

- Storage

- Optimizing tools & Techniques

- Measures of Performance

Operator Driven Reliability

- Introduction

- Role of Operator

- Total Productive Maintenance

- Work Place Organization

- Overall Equipment Efficiency

Condition Monitoring Technologies

- Introduction

- Vibration Analysis

- Thermography

- Electric Motor Testing

- Oil and Wear Particle Analysis

- NDT

Continuous Improvement

- KPI

- Review

- Continues Improvement

Course Details:

Duration:

2 days

Fee:

Rs 15,500/- Per Student

07th -08th December 2020